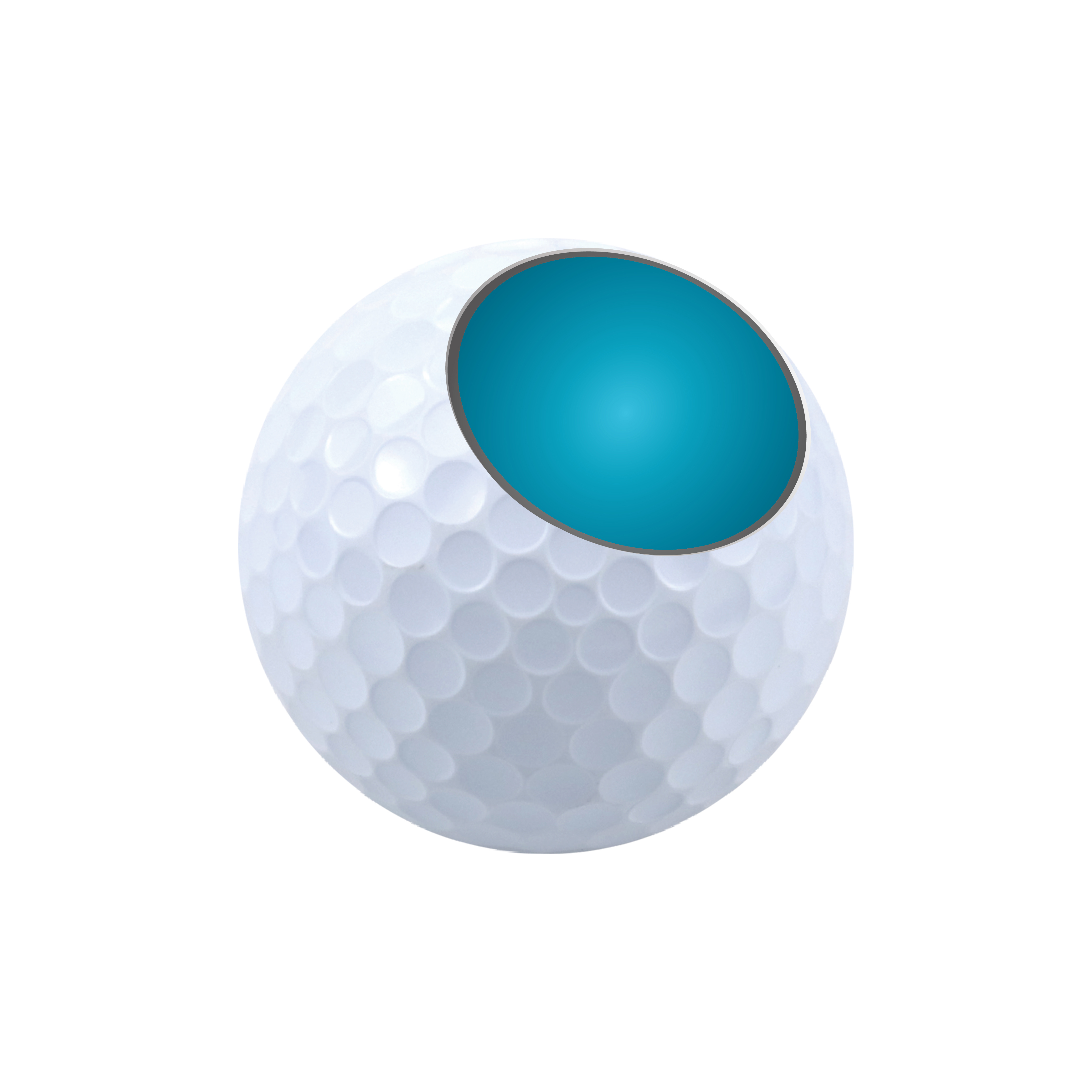

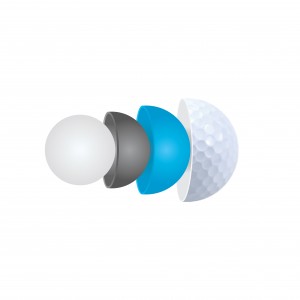

3-Layer (polyurethane) PU soft ball

Hangzhou Speed Sports Goods Co., Ltd. is affiliated with Zhonghong Holding Group, which has more than ten subsidiaries and has been rated as one of the top 500 private enterprises in China for consecutive years. Speed Sports specializes in golf ball design, production, and sales. With a manufacturing area of 7000 square meters, it currently produces more than 3 million balls per month. The company's R&D team has been committed to breaking through technical difficulties of the PU golf ball, such as wear resistance, and cutting resistance. It has passed three ISO system certifications and environmental impact assessment acceptance.Selected rubber raw materials are turned out to be golf ball core by a complete process, such as internal mixing, extrusion, hot pressing vulcanization, and grinding processing. With the help of automatic elevators and production equipment, these golf ball cores eventually become a variety of golf balls through various processes such as injection molding, rounding, printing ,spraying and drying. After multiple quality inspection processes, such as manual testing, batting, moisture content, freezing, compression, and hardness testing, the products ultimately sold to many countries and regions such as South Korea, Japan, the United States, and Europe.

Core

· Material composition: Polybutadiene

· Size: 39.10mm

· Hardness: centre 35D, surface 53D (shore D)

· Compression: 95-105

· COR: 0.786-0.798@125ft/s

Inner Cover (Mantle)

· Material composition: Surlyn ® lonomer Resin

· Size: 41.30mm

· Hardness: 58D(shore D)

· Compression: 105-110

Outer Cover

· Material composition: Urethane

· Thickness: 0.75-0.85mm

· Hardness: 53D(shore D)

· Compression: 110-115

· Dimple Type:332

· Weight: 45.55-45.85 (Finished ball)

· COR: 0.795-0.805@125ft/s (Finished ball)